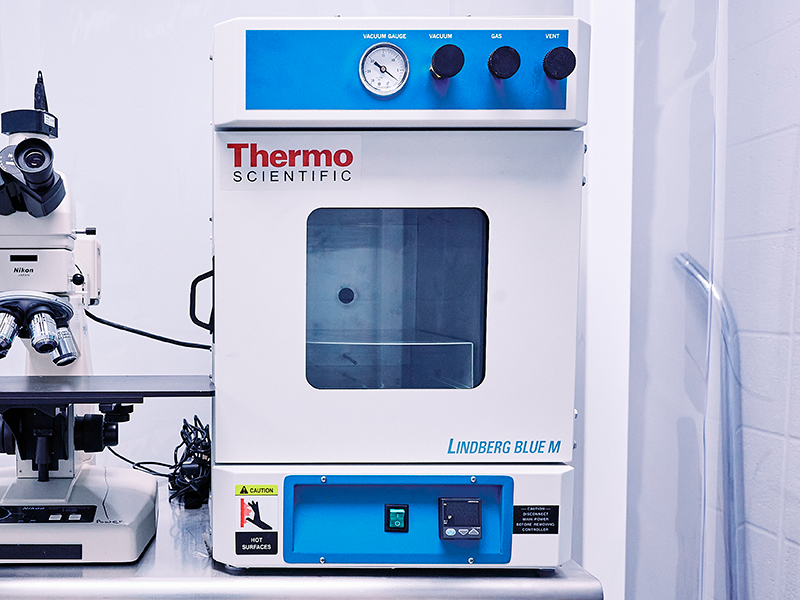

Lindberg/Blue Boron Diffusion Furnace

Description

The Lindberg/Blue Boron Diffusion Furnace is a high temperature, controlled atmosphere furnace designed for precise boron diffusion processes in semiconductor manufacturing and research applications. It features uniform temperature distribution, programmable temperature profiles, and robust construction for consistent doping of silicon wafers. Ideal for cleanroom environments, this furnace supports reliable and repeatable diffusion results.