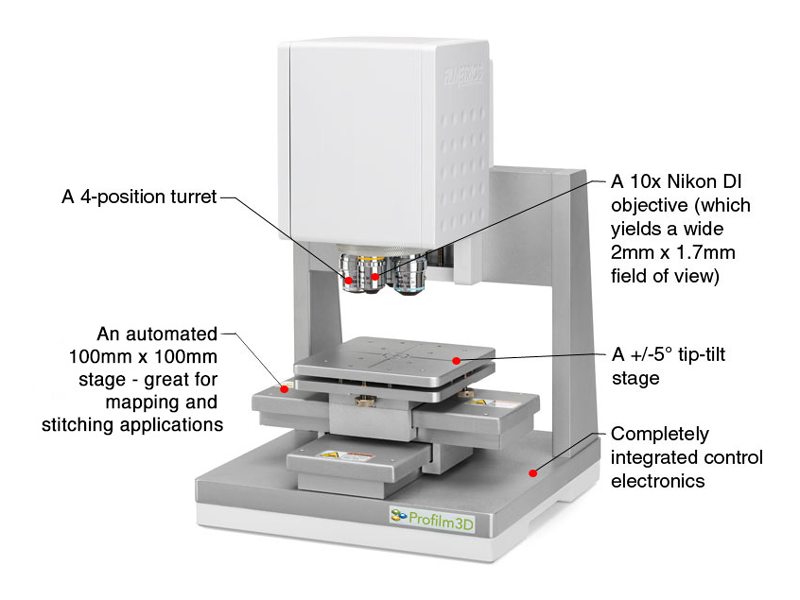

Filmetrics Profilm 3D optical profilometer

Description

The filmetrics profilm 3d optical profilometeruses state-of-the-art white light interferometry(WLI) to measure surface profiles and roughness down to 0.05µm; adding the low-cost PSI option takes the minimum vertical feature size down to 0.001µm.

Other Features

- A free online analyzer for images such as profilometer and AFM

- Intuitive Analysis Software

- All 47 standard ASME/EUR/ISO roughness parameters

- Multiple Step-height techniques: line, rectangle, and histogram

- Roughness and waviness cutoff filter

- Bearing ratio

- Spatial and FFT filtering

- Volume calculation

- Form removal

- Particles/Grains