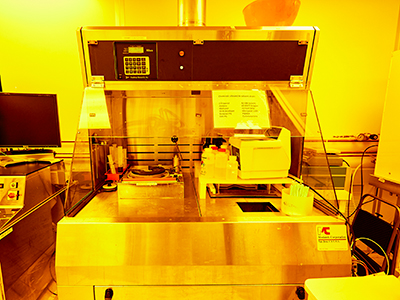

Solvent/Headway Spinner Bench

Description

Headway PR spinner & solvent bench.

Headway PR spinner & solvent bench.

Facility Manager:

Dr. Andrew Lingley

Montana State University

518 Cobleigh Hall

Bozeman, MT 59717

Phone: (406) 994-2518

Email: andrew.lingley@montana.edu

Facility Director:

Dr. David Dickensheets

Montana State University

530 Cobleigh Hall

Bozeman, MT 59717

Phone: (406) 994-7874

Email: davidd@montana.edu

Student Offices:

111 Barnard Hall

Phone: (406) 994-3112