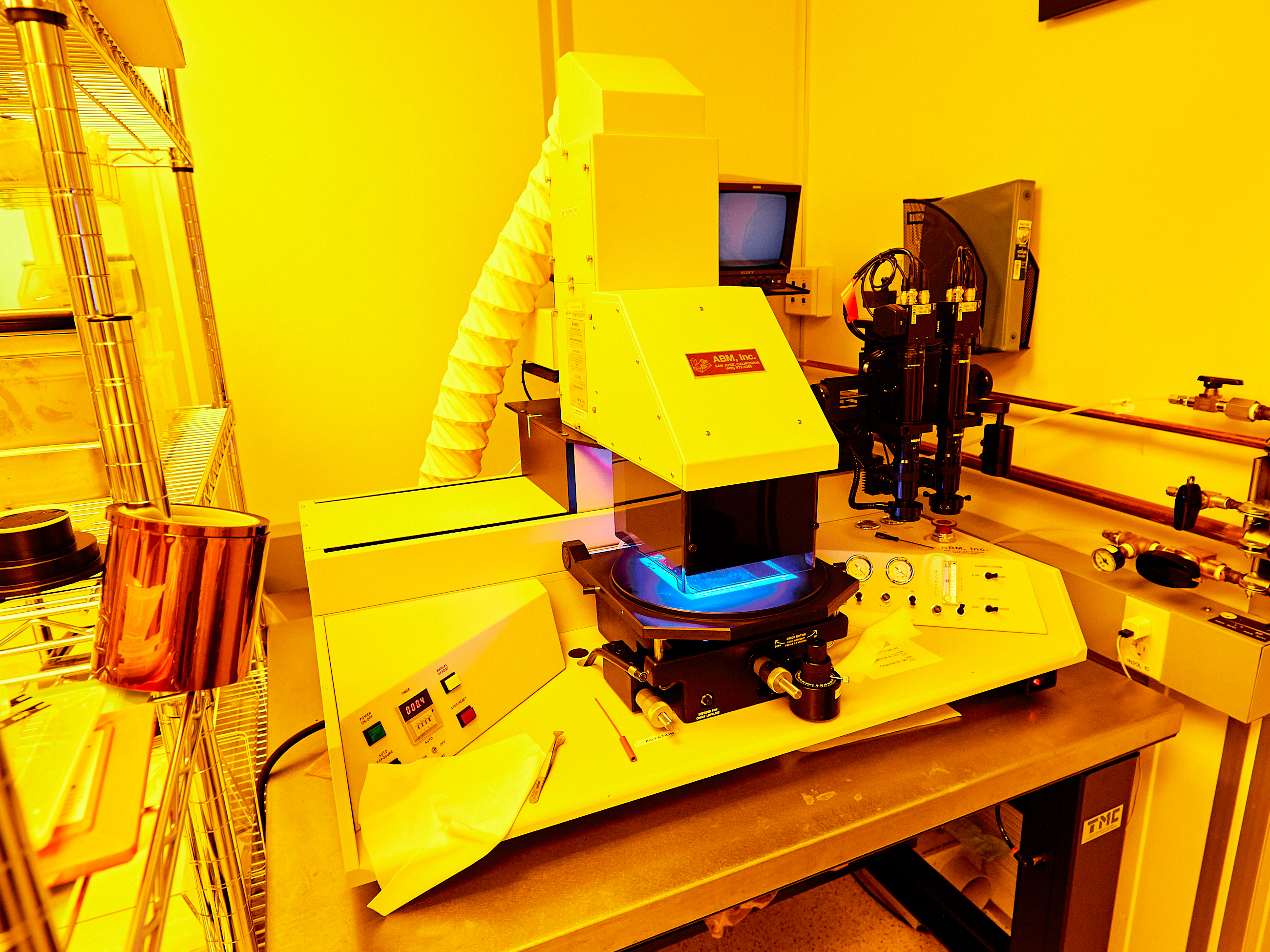

AB-M Contact Aligner

Description

The AB-M is our primary lithography tool using a broadband mercury arc lamp to expose photoresist. It is used for aligning substrates to masks, has an IR illumination system, and has a variety of filters for exposing different resist.