AZ 1512 Procedure

- Start from a clean wafer.

- Dehydration: 120°C baking for 10 mins.

- Adhesive promotor coating: Programmed HMDS coating (Program 1).

- Spin Coating: Note. To ensure adhesive promotor active, start PR spin coating right after HMDS coating.

- Dispense sufficient amount of AZ 1512 from the center of the wafer covering 60% -

70%

of the wafer surface. - Spin at 500 rpm for 20 seconds to spread out the photoresist.

- Spin at 4000 rpm for 35 seconds to reach 1.3 micrometer in thickness. (+ or – 476 nm).

- Dispense sufficient amount of AZ 1512 from the center of the wafer covering 60% -

70%

- Soft Bake: 110°C (1 min).

- Exposure: 2.4 seconds with expose dose 40 mJ.

- Develop:

- 50 seconds gentle agitation in AZ 300MIF solution.

- (Optional) Stir the wafer slightly to remove red PR residue floating on top of wafer.

- Rinsing: Dip into water to remove developer.

- Dry: Blow dry the wafer with compressed Nitrogen gun.

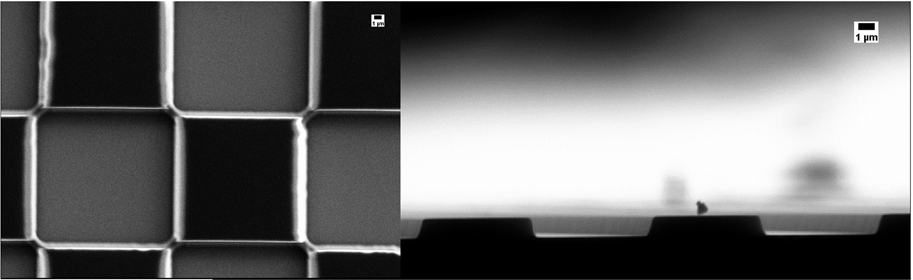

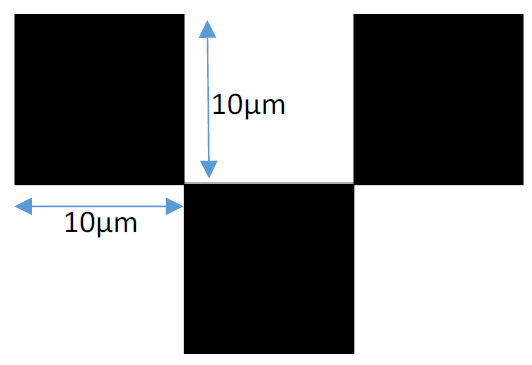

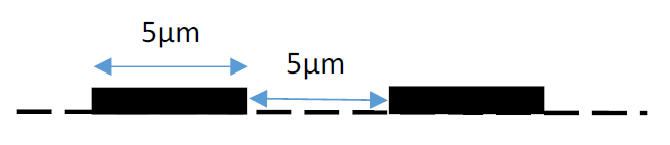

Result Expectation:

For pattern dimension larger or equal to 2 micrometers, single layer pattern has 75°

or higher cross-sectional

angle at the silicon substrate.